Blog

Material Handling Equipment in Pune | Delsol Engineering India Pvt. Ltd.

Pune has become one of India's most rapidly growing industrial centres, boasting thriving automotive, engineering, and manufacturing industries. Within these industries, material handling equipment plays a crucial role in ensuring smooth operations, minimising downtime, and maximising efficiency. At Delsol Engineering India Pvt. Ltd., we specialise in designing and manufacturing effective material handling systems in Pune, aligned with international standards and industry demands.

What is Material Handling Equipment?

Material handling equipment refers to machinery, systems, and tools utilised to move, store, control, and protect materials throughout manufacturing, warehousing, distribution, and disposal processes.

Popular Types of Material Handling Equipment

- Conveyors — Belt conveyors, screw conveyors, and chip conveyors

- Lifting Equipment — Cranes, hoists, hydraulic lifts

- Storage Systems — Racks, bins, tanks

- Automated Systems — Specialised handling solutions for specific industries

Advantages of Using Material Handling Equipment in Industries

- Improved Productivity — Enables smooth movement of raw materials and finished products.

- Reduced Labour Costs — Automation reduces reliance on manual handling.

- Enhanced Safety — Minimises workplace accidents and ensures compliance with regulations.

- Space Optimisation — Makes efficient use of floor space with storage and conveyor systems.

- Customised Solutions — Equipment tailored for specific applications in Pune industries.

Material Handling Solutions in Pune by Delsol Engineering

At Delsol Engineering India Pvt. Ltd., we are trusted manufacturers of industrial conveyors and handling systems in Pune. Our range of solutions includes:

- Belt Conveyors — Ideal for bulk material handling across industries.

- Screw Conveyors — Perfect for handling powders, chips, and semi-solid materials.

- Magnetic Chip Conveyors — Designed for CNC and machining applications.

- Roll Coolant Filtration Systems — Ensure smooth material flow and protect equipment.

Why Choose Delsol Engineering India in Pune?

- Tailor-made solutions designed as per client requirements.

- Superior manufacturing backed by stringent quality checks.

- Timely project execution across Maharashtra and India.

- Proven experience in small-scale and turnkey projects.

Conclusion

If you’re looking for reliable material handling equipment manufacturers in Pune, Delsol Engineering India Pvt. Ltd. is your trusted partner. Our innovative solutions guarantee maximum efficiency, safety, and reliability in industrial operations.

📞 Contact us today to discuss your requirements for conveyors, lifting systems, and customised material handling solutions.

Complete Guide to Water Treatment Tank Fabrication in India

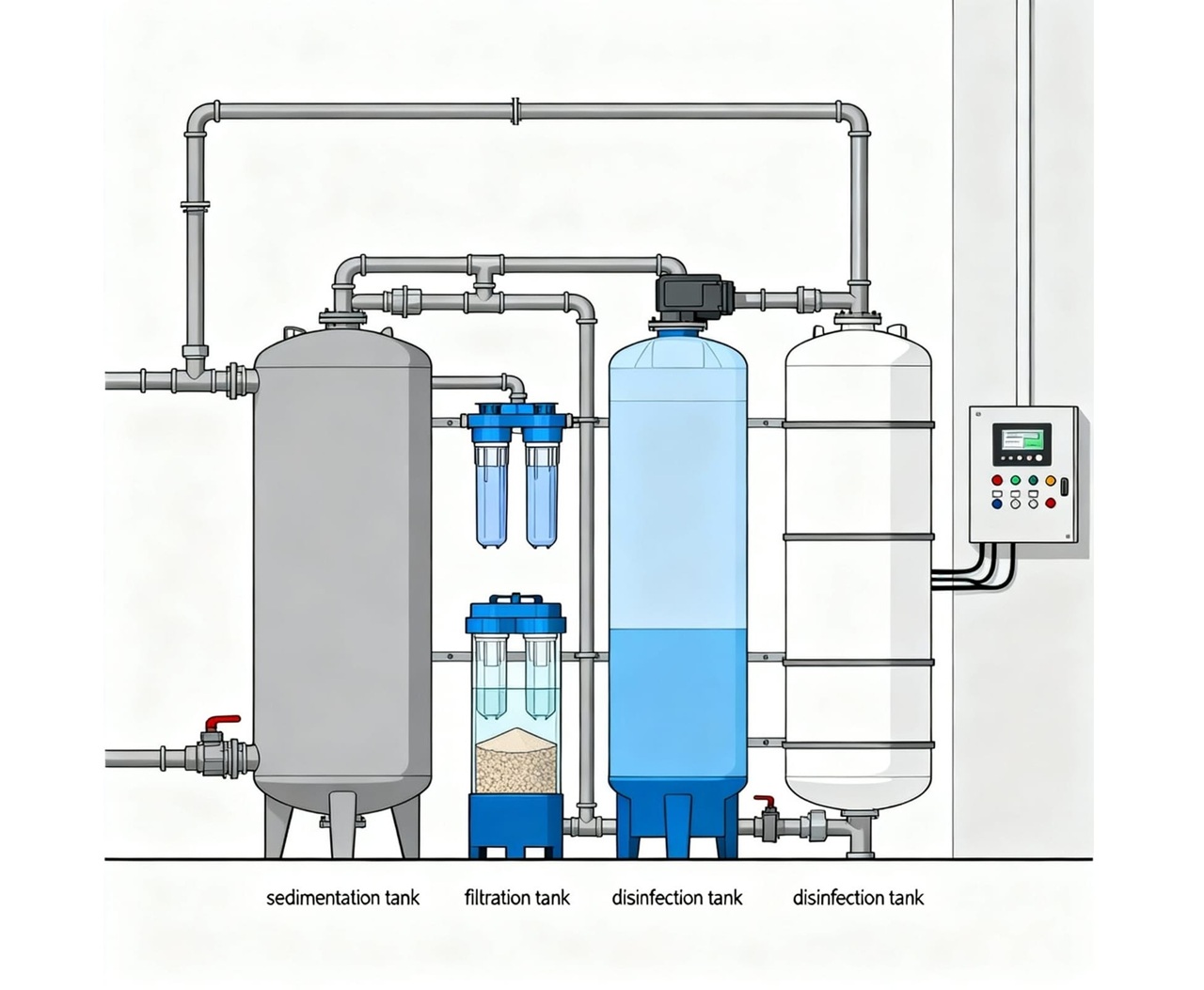

Water is a key input for industries, and efficient management of it is a must for sustainable production. Water treatment tanks are pivotal for the storage, filtration, and treatment of water for industrial use. Be it product quality or environmental compliance, these tanks are essential for industries such as textiles, chemicals, pharmaceuticals, and food processing. High-quality water treatment tanks help improve operational efficiency and minimize wastage.

What is Water Treatment Tank Fabrication?

Water treatment tank fabrication is the process of designing and manufacturing tanks that store, process, or treat water based on industrial requirements. Unlike standard storage tanks, these tanks are built to withstand chemical reactions, pressure variations, and long-term exposure to water and wastewater.

Key Fabrication Steps:

- Precise measurements

- Cutting and welding

- Assembling using specialized materials and techniques

Materials & Techniques Used in Fabrication

Choosing the right materials and fabrication techniques is crucial for the longevity and performance of water treatment tanks.

- Mild Steel (MS): Cost-effective, suitable for general industrial water storage.

- Stainless Steel (SS 304 / SS 316): Corrosion-resistant, ideal for chemical and pharmaceutical industries.

- Fiber-Reinforced Plastic (FRP): Lightweight and chemical-resistant.

- Polyethylene (HDPE / LDPE): Non-corrosive, commonly used for small-scale systems.

Industry Applications

- Textiles: Dyeing, washing, and water recycling.

- Chemicals: Industrial effluent storage and treatment.

- Pharmaceuticals: Sterile water for production processes.

- Food & Beverages: Clean water for processing and sanitation.

- Power Plants & Manufacturing: Cooling water, boiler feed, and wastewater treatment.

Choosing the Right Fabrication Partner

- Experience & Expertise: Years of fabrication experience in your industry.

- Customization Capabilities: Ability to design tanks per specifications.

- Quality Assurance: Compliance with IS, ASTM, and ISO standards.

- After-Sales Support: Installation, maintenance, and repair services.

Why Indian Manufacturers Stand Out

- Skilled Workforce: Experienced engineers and fabricators.

- Advanced Manufacturing Facilities: Modern machinery and techniques.

- Cost Efficiency: Competitive pricing without compromising quality.

- Customization Expertise: Ability to cater to diverse industry needs.

- Timely Delivery: Efficient project management and logistics support.

Conclusion & Call-to-Action

Water treatment tanks are cornerstones of industrial water management. Choosing the right materials, fabrication techniques, and manufacturing partner ensures efficiency, safety, and sustainability.

If you are looking for customized, durable, and cost-effective water treatment tanks in India, Delsol Engineering India Pvt Ltd. offers end-to-end solutions—from design and fabrication to installation and maintenance.

Contact us today to discuss your requirements and get a free consultation for your next project.

Top Water Treatment Tank Manufacturers in India – Quality & Reliability

With the growing demand for sustainable and efficient water management, the need for high-quality water treatment tanks is rapidly increasing. India has become a trusted destination for top-quality water tank manufacturers, tank manufacturer Pune India, customise tank manufacturer, customise tank manufacturer Pune India, waste water tank fabricator, and sewage tank manufacturer.

Growing Demand for Water Treatment Tanks

Industries across India are focusing on clean water usage, wastewater recycling, and sewage treatment. As a result, the role of every reliable water tank manufacturer and customise tank manufacturer Pune has become vital in building efficient, durable, and corrosion-resistant systems.

Role of Manufacturers in Ensuring Quality Standards

A professional waste water tank manufacturer ensures precision design, long life, and quality standards. Reputed tank manufacturers in Pune use certified materials like SS304 and SS316, along with advanced welding and fabrication techniques. Whether it’s a water tank fabricator or (STP) sewage tank manufacturer, the focus remains on strength, reliability, and quality.

Key Features to Look for in a Reliable Manufacturer

When choosing a customise tank manufacturer or water tank fabricator, consider:

- Experience in water treatment and sewage tank fabrication

- Capability to design customise tanks as per project needs

- Use of high-grade stainless steel materials

- Quality testing and inspection before delivery

- Proven track record among tank manufacturers in Pune India.

A professional customise tank manufacturer Pune India can deliver long-lasting, maintenance-free water treatment tanks and (WTP) water sewage treatment tanks for industrial applications.

Export Opportunities from India

India’s water tank manufacturers and sewage tank manufacturers are now exporting globally. With superior engineering, cost efficiency, and customization options, tank manufacturers in Pune and across India are serving clients in Asia, the Middle East, and Africa. Indian customise tank manufacturers are becoming globally trusted partners.

Industries Served

- Water and Wastewater Treatment Plants (WTP/STP)

- Chemical and Process Industries

- Food, Dairy, and Beverage Plants

- Pharmaceutical and Biotech Sectors

- Power and Energy Projects

Each industry requires a customise tank manufacturer capable of meeting exact client specifications with durable water treatment tanks and sewage tanks.

Why Choose Us as Your Trusted Partner

Delsol Industries is one of the leading water tank manufacturers and customise tank manufacturer Pune India. We specialize in manufacturing and fabricating high-quality water treatment tanks, sewage tanks, and process tanks using the best raw materials and fabrication practices. As a trusted tank manufacturer Pune, we ensure superior quality, timely delivery, and complete customization.

If you are searching for a reliable water tank manufacturer, water tank fabricator, or sewage tank manufacturer, Delsol Industries is your one-stop solution.

Conclusion and Call to Action

Partner with a trusted water tank manufacturer in Pune who understands your requirements and delivers quality beyond expectations. Choose Delsol Industries – your reliable water tank manufacturer, customise tank manufacturer Pune, and water tank fabricator for all industrial tank needs.

📞 Contact us today or visit 🌐 www.delsolindia.com to know more about our water treatment tank manufacturing solutions.

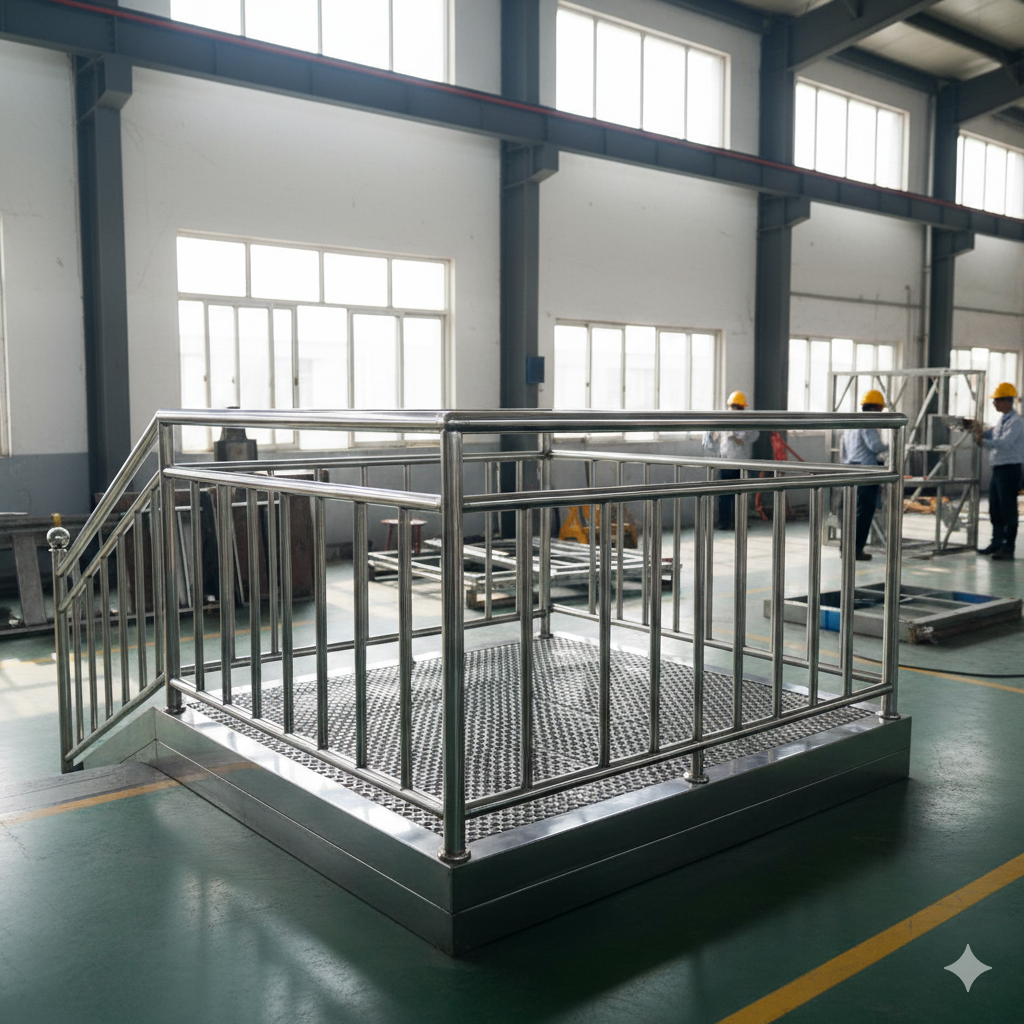

Platform Railing Fabrication – Safety, Design & Industrial Applications

In industrial environments, safety and structural strength are top priorities. Platform railing fabrication plays a vital role in preventing accidents, ensuring worker stability, and maintaining compliance with safety standards. Whether it’s a factory floor, warehouse mezzanine, or power plant, platform railings safeguard personnel and equipment while promoting a secure and efficient workspace.

Introduction – Importance of Platform Railings

In industrial environments, safety and structural strength are top priorities. Platform railing fabrication plays a vital role in preventing accidents, ensuring worker stability, and maintaining compliance with safety standards. Whether it’s a factory floor, warehouse mezzanine, or power plant, platform railings safeguard personnel and equipment while promoting a secure and efficient workspace.

Design & Safety Standards in Platform Railing Manufacturing

At Delsol Engineering India Pvt. Ltd., a leading platform railing manufacturer in Pune, India, we follow strict industrial design and safety standards during fabrication. Each industrial railing fabrication project is developed in compliance with OSHA and IS standards, ensuring proper height, spacing, and load-bearing capacity.

- Ergonomic and safe designs for worker comfort.

- Slip-resistant and corrosion-proof finishes for long-term reliability.

- Strong structural support for heavy-duty applications.

- Compliance with industrial safety fabrication norms and quality certifications.

Our attention to detail ensures that every customized railing system provides maximum safety and durability in demanding industrial conditions.

Materials Used in Platform Railing Fabrication

Delsol Engineering utilizes high-grade materials for superior performance and long service life:

- Mild Steel (MS): Durable, economical, and easy to weld or coat.

- Stainless Steel (SS 304/316): Corrosion-resistant and suitable for cleanroom or outdoor use.

- Aluminium: Lightweight, non-corrosive, and ideal for specialized applications.

Each platform railing can be powder-coated, galvanized, or painted as per client specifications, ensuring durability even in harsh industrial environments.

Industrial Applications

Our platform railing systems are used across a wide range of industries, including:

- Manufacturing Plants – For mezzanines, machine platforms, and operator walkways.

- Warehouses & Logistics Centers – For raised storage areas and loading zones.

- Chemical & Power Plants – For corrosion-resistant, safety-critical operations.

- Construction Sites – Temporary or permanent safety railings for worker protection.

These structural fabrication systems are easy to install, low-maintenance, and can be tailored for any industrial layout or space requirement.

Benefits of Customized Railing Systems

Choosing customized railing systems from Delsol Engineering provides:

- A perfect fit for your specific platform configurations.

- Enhanced worker safety and visual appeal.

- Modular or detachable railing options.

- Cost-effective solutions with minimal maintenance.

With every project, we ensure precise engineering, premium welding quality, and timely delivery—hallmarks of a trusted industrial fabricator in Pune.

Indian Expertise in Platform Railing Fabrication

As one of the most reliable names in industrial fabrication, Delsol Engineering India Pvt. Ltd. has successfully completed numerous platform railing fabrication projects across India. Our in-house design, production, and installation capabilities make us a one-stop solution for platform railing manufacturer and fabricator services.

We take pride in being recognized as a trusted railing manufacturer in India, known for our commitment to quality, durability, and innovation in industrial safety fabrication.

Conclusion & Call to Action

A well-built platform railing is more than a safety requirement—it’s an investment in workplace safety and long-term productivity.

👉 Partner with Delsol Engineering India Pvt. Ltd. for reliable, customized, and high-quality platform railing fabrication solutions tailored to your industrial needs.

📞 Contact us today or visit 🌐 www.delsolindia.com to learn more.

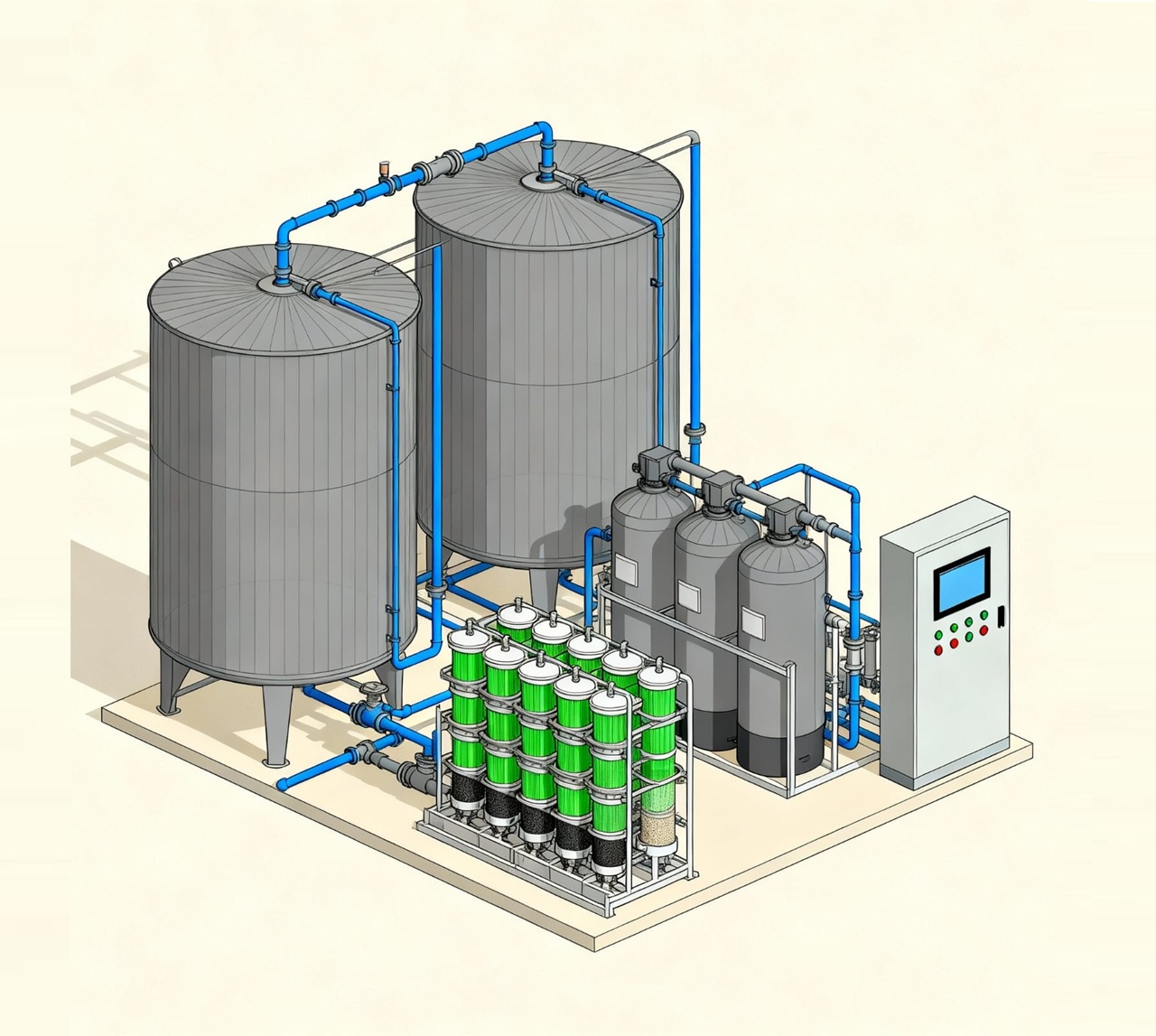

How Delsol Engineering Ensures Quality and Precision in Skid Fabrication

When it comes to industrial projects, precision and reliability are crucial. At Delsol Engineering India Pvt. Ltd., we specialize in high-quality skid fabrication in Pune — offering complete design, engineering, and manufacturing solutions. As a trusted skid manufacturer and fabricator in India, we deliver customised skid fabrication services that ensure strength, durability, and long-term performance.

Step-by-Step Quality Fabrication Process

1. Customised Design and Engineering

Every project begins with a deep understanding of your process requirements. Our design experts use advanced 3D CAD modeling to create customised skid systems — ensuring accurate alignment of pumps, tanks, motors, and equipment. This results in one of the most precise customised skid fabrication solutions in Pune.

2. High-Quality Material Selection

We use premium-grade materials such as MS, SS304, and SS316 based on client needs. Each batch undergoes strict quality checks to ensure corrosion resistance, strength, and long-term durability — setting us apart as a reliable skid fabricator in Pune, India.

3. Precision Fabrication Techniques

Our fabrication team follows advanced MIG/TIG welding and CNC cutting processes. Every skid frame is fabricated on precision-level platforms, ensuring perfect alignment, stability, and vibration-free performance.

4. Surface Finishing & Coating

Each skid undergoes sandblasting, primer application, and epoxy or PU coating. This multilayer finishing protects against rust and industrial wear while ensuring long operational life.

5. Quality Testing and Inspection

Before dispatch, every skid system undergoes multiple inspections — including weld checks, alignment analysis, load testing, and dimensional accuracy verification. This ensures ISO-compliant quality and consistent performance.

6. Packaging and Timely Delivery

We ensure safe, damage-proof packaging and guaranteed on-time delivery across India. Our logistics team ensures seamless transport for every skid fabrication and manufacturing project handled by Delsol Engineering.

Why Choose Delsol Engineering Pune for Skid Fabrication?

- Expertise in customised skid fabrication Pune and across India

- Advanced in-house design, fabrication & testing facilities

- Experience in STP/WTP, oil & gas, process industries

- Dedicated QA/QC inspection team

- Trusted nationwide as a premium skid manufacturer & fabricator

Conclusion

At Delsol Engineering India Pvt. Ltd., we combine innovation, precision, and craftsmanship to deliver high-performing skid systems for industries across India. Whether it’s a base frame, pump skid, or customised process skid, we provide premium-quality skid fabrication solutions in Pune.

📍 Location: Pune, Maharashtra

📞 Contact: 7263030707

🌐 Website: www.delsolindia.com